Red viscose satin COUPON 110 cm

Navy blue viscose satin

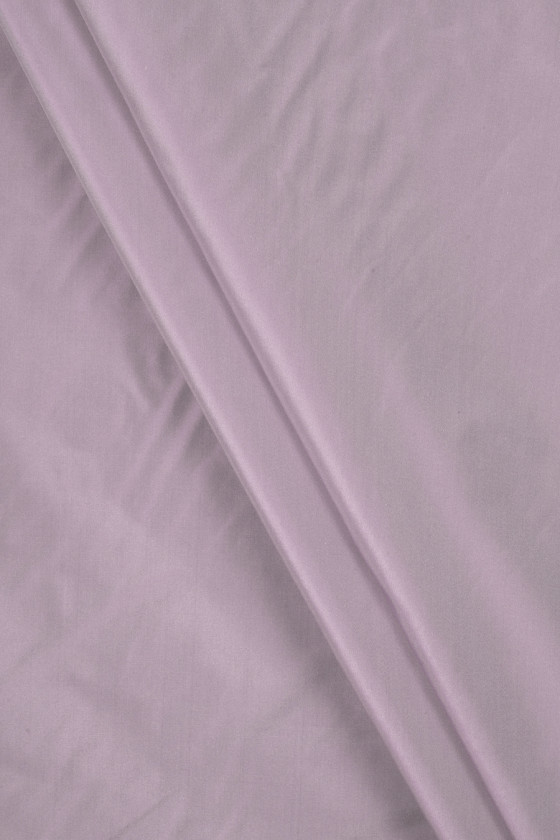

Viscose Pink Satin

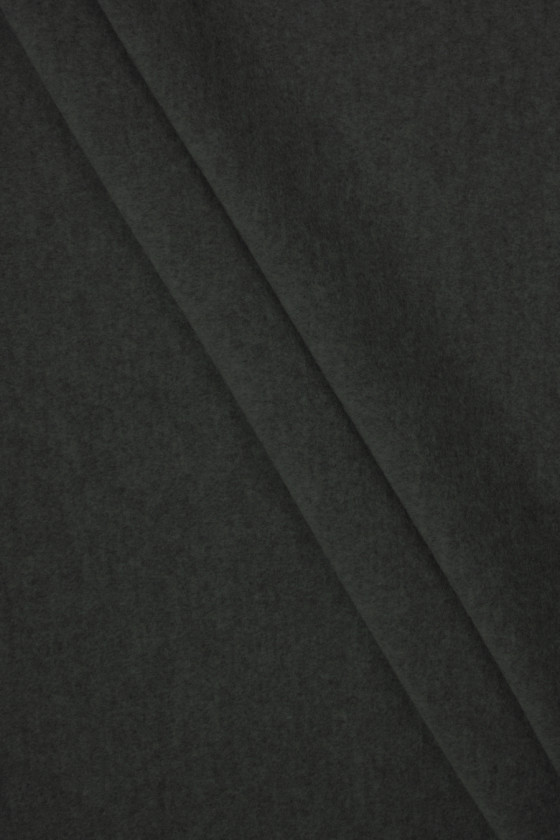

Graphite sheath wool

Honey coat wool

Viscose satin candy pink

Cornflower costume wool

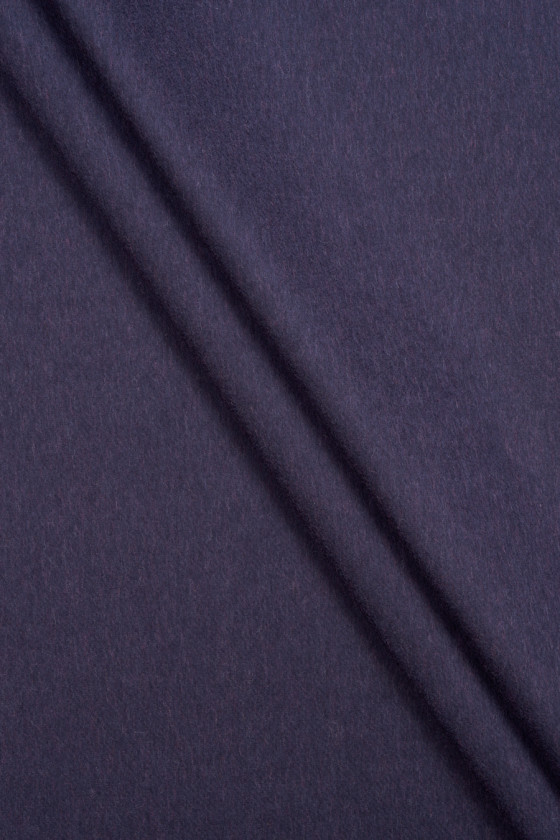

Costume wool merino dark navy blue

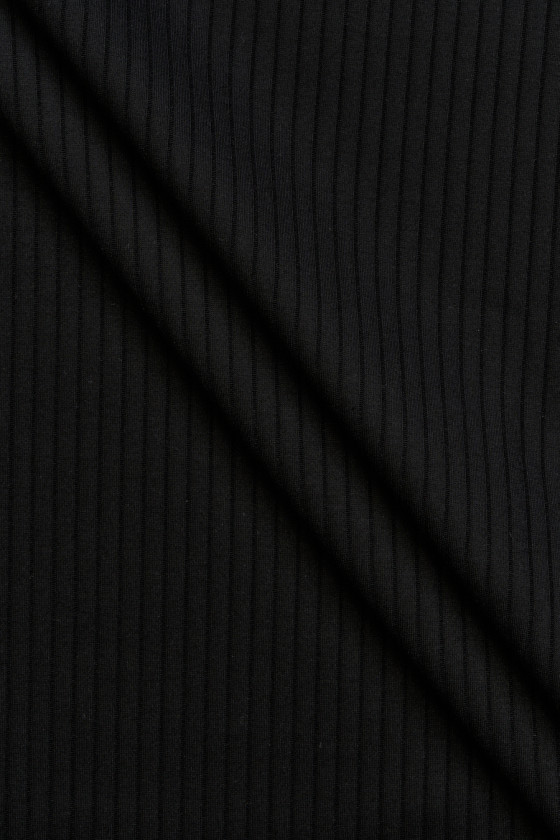

Marine ribbed knit fabric

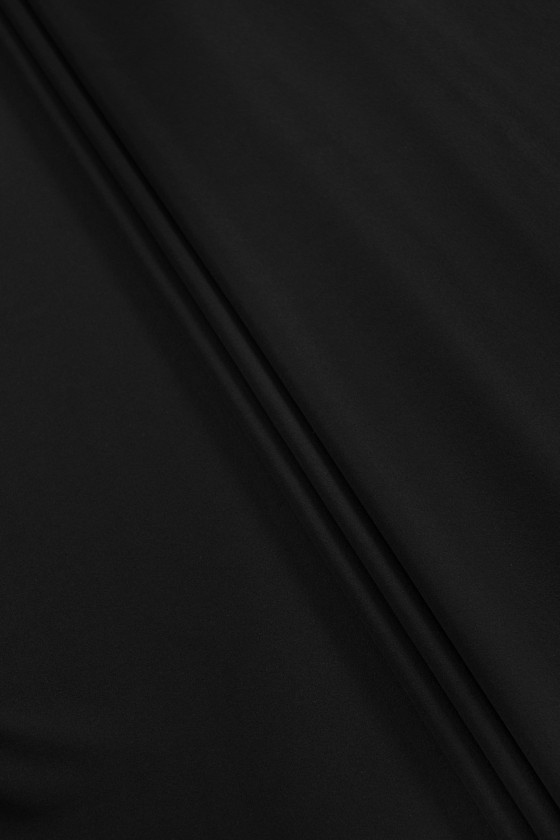

Cadi acetate with silk black

Ribbed knit - various colors

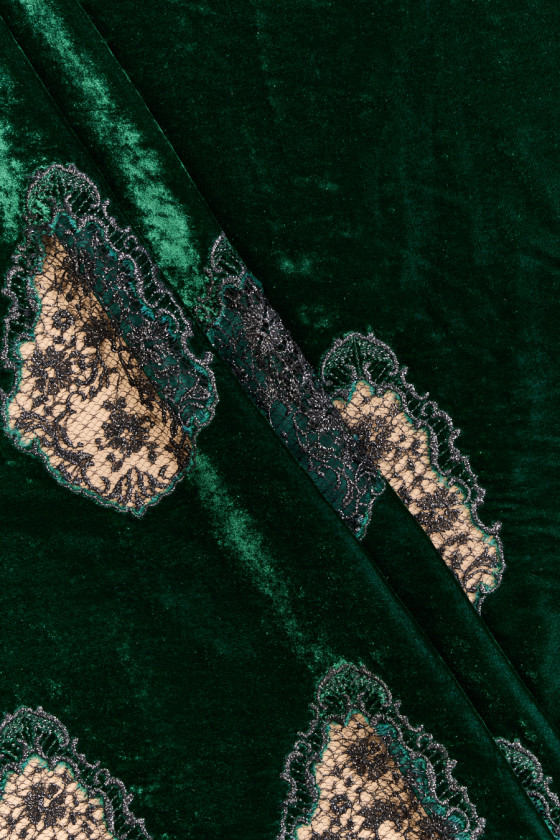

Exclusive velour with lace

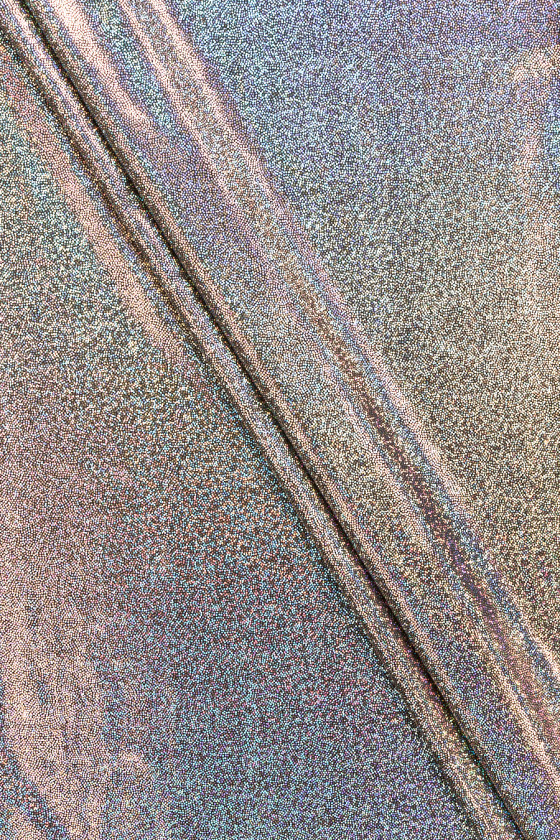

Exclusive velour with glitter

Gold polyester organza

Black Lycra with glitter

Gold Lycra with glitter

New - Cadi T Dress - Assorted Colors

Navy blue wool Zibellino

Purple wool Zibellino

Coat wool orange Zibellino

Beige wool Zibellino

Exclusive feather tape

Silk crepe with colorful stripes

Champagne flax

Olive flax

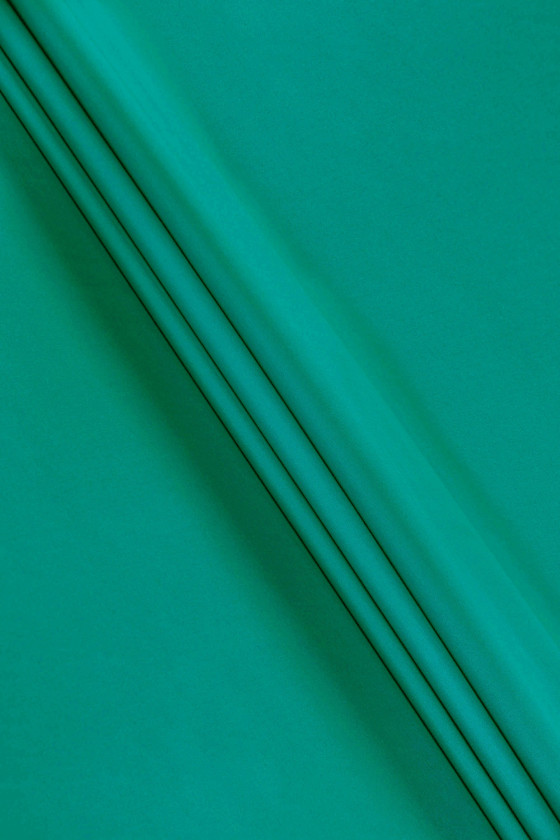

Elastic green cotton

Lemon elastic cotton

Elastic yellow cotton

Elastic cotton light turquoise

Elastic blue cotton

Sea elastic cotton

Polyester taffeta two-tone

Green polyester taffeta

Polyester taffeta sharp pink

Shandong silk cold beige

Shantung silk light pink

Cadi acetate with viscose black

Linen with cotton like jeans COUPON 110 cm

Costume wool navy blue twotone

Natural flax - mustard

Natural flax - cream

Wool is one of the oldest textile fibres used by man. It is a natural fiber, usually obtained from sheep. It is used for the production of clothing, accessories such as hats or gloves, but blankets or carpets are also made of it. It works well as a smooth woolen fabric, but also for creating patterns in textiles. It can be dyed, thanks to which it is available in many colors.

Wool is also biodegradable, which means that it can decompose naturally. Thanks to this, it is more environmentally friendly than synthetic fibers.

How is wool made?

The process of formation of smooth wool consists of several stages. Before a smooth woolen fabric is formed, the fleece has to go a long way.

The first stage is cleaning, because wool obtained from sheep contains fat and many other impurities, such as sand or dust. Cleaning is carried out in a special machine that removes all the dirt, and then the washed fiber is dried. Before spinning, a preparation is applied to the wool, which reduces friction between the fibers and the metal elements of the spinning machine. Before spinning, wool is also dyed if it is to acquire a color other than natural.

After that, the spinning process begins, which is carried out in different ways, depending on the thickness of the wool. In a nutshell, it consists in stretching the fibers and giving them the right twist, and then winding them on the yarn.

The next stage is weaving the prepared wool. Weaving involves forming fabric by interlacing yarn at the right angle on a loom.

The final stage is a thorough check of the fabric. Particularly smooth fabrics are carefully checked for any blemishes formed during the earlier stages. Then the fabrics are washed.

Smooth wool fabric is also in some cases protected with special rain protection agents. Thanks to this, jackets or coats sewn from them do not absorb water. The finished fabric is delivered to fabric stores or sewing rooms, where individual items of clothing will be made of it. As a curiosity, it is worth mentioning that the quality of wool depends not only on the breed of sheep, but also on the part from which it was obtained. Wool from the head, legs and tail is mostly rough and requires longer washing at the stage of formation. The best wool is obtained from the sides and it is from it that smooth fabrics are made, the most pleasant to the touch.

Types of plain fabrics

The most popular and known is, of course, sheep's wool, from which we can make, among other things, smooth fabric. However, it is worth mentioning other animals from which wool is obtained. These are primarily:

- Angora goats from which mohe r is obtained - it is a flexible wool and resistant to creases,

- cashmere goats - it is from their wool that cashmere is made, an extremely pleasant, smooth fabric, considered one of the most exclusive and achieving the highest prices,

- llamas and alpacas whose wool is characterized by endurance and hypoallergenicity,

- musk oxen giving light and soft wool, and at the same time considered the warmest in the world,

- Angora rabbits, whose long coat produces a fine yarn, known as angora.

Characteristics of wool

Wool is one of the most popular materials. It is difficult for us to imagine our wardrobe of woolen clothing or accessories. Despite the growing popularity of synthetic materials, smooth woolen fabric, thanks to its properties, will not be replaced by them for a long time.

Wool perfectly insulates, both from cold and heat. It reacts to temperature changes and can be worn all year round. It is a breathable material that perfectly absorbs moisture from the body. It is durable and not easily dirty. Wool is also light and comfortable to wear, thanks to which even several layers of woolen clothing do not restrict our movements and do not give a feeling of discomfort.

These smooth fabrics are crease-resistant and at the same time easy to dye, so we are able to get a huge palette of colors for every item of clothing.

In order for woolen clothing to serve us as long as possible, in perfect condition, it is important to take care of it properly. Wool products should be washed sparingly, preferably by hand, possibly using programs typical for washing wool. Let's also give up strong detergents. We dry woolen clothes spreading them flat on a towel at room temperature.

So where can smooth woolen fabrics be used?

Properly impregnated, they will work well in the case of outerwear such as jackets or coats. Smooth fabrics can be used to sew dresses, jackets, trousers and skirts. Woolen yarn will be used to make sweaters, scarves, hats, gloves and socks.

Wool has also found its application as a fabric for interior design. Thick blankets, bedspreads or carpets will add coziness to the interior.

The use of wool is also beneficial for the environment. Unused wool products can be recycled. Those that are not suitable for this will decompose much faster than synthetic materials, and do not emit harmful substances.

Write to us on WhatsApp!